Applicable Skills

- Teamwork & Cooperation

- Coordinating & Planning

- AutoCAD Solid-modelling

- 3D Printing and Assembly

Patient History

Kenny Baniah is an ostomy patient who’s had a colostomy and has faced multiple issues due to his 2-piece ostomy system. His higher BMI has made concave ostomy skin flanges very uncomfortable for him, forcing him to switch to a flat skin flange for comfort. This, however, caused leakages along with Ulcerative Colitis; or inflammation in the large intestine. To solve this problem, we decided that we needed to create distance between the ostomy bag and Kenny’s skin to ease the pressure off his abdomen.

Design Process

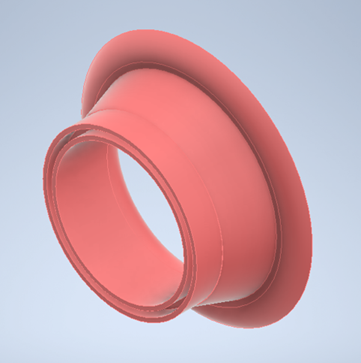

My main thinking involved finding a way to take advantage of available materials to replace the plastic in conventional skin flanges. Small cut piece of PVC piping is used to represent a tunnel for excretions to move to the ostomy bag without direct skin contact. Conventional skin flanges are replaced with a stretchable material to eliminate abdominal pressure. A 3D-printed model of these attachments would create a tight seal with the skin, held together using kinetic tape commonly used in physiotherapy practices.